Five problems with process improvement workshops

Process improvement workshops are the norm for analysing, identifying and deciding on process improvement initiatives. While they have their strengths on a team level they show their limitations when we’re trying to improve cross-functional business processes.

This is the second post in a small series on “Barriers to Lean Management“. The barriers for Lean Management exist simply because some basic assumptions for practising Lean are not met. The most fundamental one relates to complexity from working with people across time and space.

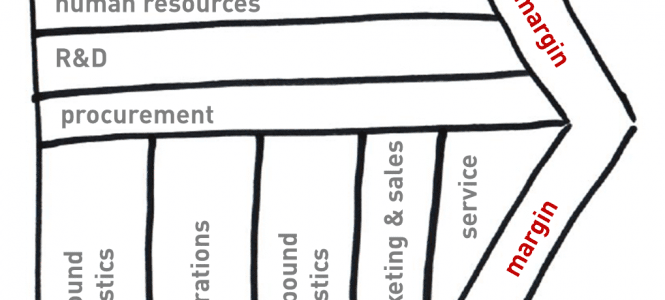

Many teams hold short daily or weekly meetings in front of their Kaizen boards. These are valuable when keeping improvements on top of everyone’s agenda and ensuring the follow-up that is required for process improvement to happen continuously. So, what happens when processes span organisational boundaries? When people lose their proximity to the process, its inputs, outputs and the other people that work with it. The Toyota factory floor (where everyone can rely on tacit knowledge) is very far away when we’re trying to use process improvement in cross-functional business processes. The cross-functional process doesn’t have the common ground that is required for effective collaboration. How can a process improvement workshop be used?

Often Managers try to recreate the common ground by using physical workshops. People then fly in for a few days to make the most of the visit and the short daily, or weekly, meetings turn into long, less frequent workshops. Much value is lost in this change. I can think of five problems that are inherent to typical cross-functional workshops:

1. Functional experts fail to understand each other’s perspectives

Most often you need to bring people from across the value chain together to find the cross-functional improvement opportunities. However, when these people only meet rarely then they have no opportunity to develop a common language and a holistic view of the business. The finance manager wants to keep inventory very low. The sales manager wants to keep it high, so he can meet any demand. The purchaser wants to use standard components. The marketer wants to differentiate. And so on. When everyone is focused on his KPIs and the interests of his function, then there simply isn’t the common ground that is required for collaborative innovation. There is no cross-functional culture or team spirit and participants may not have the ability to look across the company after years of perfecting their functional skills. This is where process improvement workshops are like to fail.

2. You don’t bring up detail in large groups of people

Process improvement is based on the premise that people reflect on what can be done better on a daily basis. Even if the people attending the workshop have documented ideas on a daily basis then a workshop with many people is a poor setting for bringing up detail. Let’s assume that 10 managers and SMEs have flown in for a three-day workshop. Each of them will be conscious of how they present themselves to others. They are therefore likely to leave details behind. If they don’t, then they risk being perceived as “someone who is good on detail but lacks overview.” That’s not a good label for ambitious people in many organisations.

Try Gluu for free

Sign up for a 30-day trial.

No credit card required.

3. The ideas you come by on a daily basis are forgotten

Have you experienced days when ideas come to you that are not directly related to the work you do? “We really should develop a better spreadsheet to handle the data for this monthly forecast.” Sometimes you note it down (and then forget about it). Most times you think that someone else will pick it up and you simply move on with what you were doing.

A better spreadsheet for a monthly forecast may save four hours every month. That is 48 hours every year for one sales office. If you have 50 offices then it amounts to 2,400 hours per year. That is more than a full-time position (assuming an FTE has 2,080 hours per year). What may seem like a detail to some may make a real difference in a large company. These ideas die along the way to the quarterly (or annual) process improvement workshops.

4. Prioritisation crowds out the small improvements

Even if “small” improvement ideas are brought to process improvement workshops, then the time is quickly consumed and these ideas naturally move down on prioritisation lists. Don’t get me wrong. Prioritisation and the 80/20 rule are critical business tools. However, it is a shame if our lack of collaboration time means that only the top 10 ideas are addressed. If time wasn’t limited then every idea that reduced waste should be implemented. Our workshop culture and governance just stand in the way for this being an effective process improvement method. To identify tools that streamline and prioritize process improvements effectively, visit our BPM Software Selection Guide for detailed recommendations on business process management platforms.

5. Some people speak, others are quiet in process improvement workshops

Some people are more introverted than others. They are often the analytical types and the ones that execute many of the processes. When they attend workshops with senior managers they tend to keep quiet. When staff are quiet, important details are not brought forward. Not because such detail is not relevant but simply because of the dynamics of a cross-functional workshop.

Cross-functional process improvement work is difficult and time-consuming but it is also where the biggest potential value is. So, what can be done about these problems? First, I would not advocate eliminating the cross-functional workshops. They are very important in creating a team feeling and establishing goal alignment. However, when it comes to the actual improvement brainstorms and conducting the PDCA cycles, then I think most workshops would benefit for follow-up dialogue in virtual collaboration rooms. Although they are only second best to short, frequent and physical meetings they have the benefit that they can happen across time and space, which is invaluable in a dispersed or virtual organisation.

Want to involve people in a planned way? Our Process Success Guide contains a full step-by-step guide to creating your own process improvement plan.

Try Gluu for free

Sign up for a 30-day trial.

No credit card required.

Frequently Asked Questions

Process improvement workshops aim to enhance business operations by fostering collaboration among team members to identify, plan, and implement improvements in existing processes. These upgrades lead to greater efficiency and productivity, lower costs, and increased customer satisfaction and profit.

The workshop is split into three stages – Tune-up, Upgrade, and Uplift. Tune-up involves analyzing current processes and identifying areas of improvement. Upgrade focuses on creating a new, efficient design for the identified process. Uplift is where this new design is implemented and optimized based on feedback.

Workshops typically consist of varied hosts and participants from different departments and hierarchy levels, carefully selected to provide a holistic view of processes and bring diverse insights.

About the Author