Are you on a path into a process wilderness?

If Business Process Management is failing, then what do the BPM Implementation Steps to failure look like? Business Process Management successes are widely promoted, its failures are hidden. Often we learn more from a failure than a success. This is a story about a company that did everything right in their business process implementation and still ended up failing. Read it and consider where your company’s path of business process implementation leads to.

Table of contents

- First four months: Setting up the project

- Eight months into the journey: Processes are mapped and presented

- 14 months into the journey: The ERP system is ready to be rolled out

- After 17 months: The change program is being prepared

- The change program is starting

- The new processes and the new ERP system go live

- The year when reality hits Nordic

- Two years after The program is completed

- Is Nordic Market a typical BPM implementation case?

- Interested in exploring how to make processes agile?

- Conclusions

- Frequently Asked Questions

This is about Nordic Market. Nordic is a Scandinavian supermarket chain. It doesn’t exist. It’s a summary of 12 real cases from industries such as transportation, shipping, manufacturing, beverages, and engineering. Some have followed the same path of processes as Nordic Market, following BPM Implementation Steps, and have realized that they have been chasing a Fata Morgana. Others are well underway deep into the desert, following BPM Implementation Steps. They are accompanied by their eager local guides in the form of well-meaning consultants, providing insights into BPM Implementation Steps. I know their stories, their aspirations, and their worries because I talk with their executives, their managers, and their front-line people every week.

First four months: Setting up the project

Nordic Market’s business process implementation journey started three years ago. The Board of Management (BoM) of Nordic introduced new management tools once in a while, following BPM Implementation Steps.. They usually came with a new executive who had experience with the tool from a previous company, or who had attended a conference. Sometimes the new thinking was embedded into Nordic’s ways of working and created some value. Other times this didn’t happen. Business Process Management was introduced when Nordic decided to introduce a common ERP system. Now all the chain’s supermarkets and central functions should use the same system for managing operations. Nordic started out with an assessment of the company’s readiness. The result was discouraging. Hardly any business processes were documented. Different functions had documented a few critical processes here and there but there was no common standard, following BPM Implementation Steps. No common perspective.

Nordic’s BoM solicited advice from external experts. On the basis of their recommendations, they decided to start a Business Process Management project. A project team was set up. The project leader then hired a well-known consulting company to assist with the project. They placed 10 full-time consultants on the project. The consultants recommended that Nordic should buy a tool to help design the processes and the business process implementation. Nordic then bought an advanced process modelling tool from a leading vendor that was right up there in the left-hand corner of Gartner’s quadrant. The team made a project plan that was approved by the BoM.

During four months the team would interview managers and subject matter experts in all of Nordic’s business functions and regions. With this knowledge, they would select and map all the company’s primary business processes which were to become part of the ERP system. The team picked BPMN as their modelling language. This standard was already used by the ERP software vendor and according to Gartner and Forrester, it was the most widely used language. Everything was done just by the book.

Then the team started creating an especially intense and busy period. Interviews were conducted through some personal visits to stores and some were done by telephone. The conversations resulted in detailed notes that became the starting points for process modelling. In most cases, so-called “industry prints” from the consulting company were used as a basis for this. After each process was modelled the consultants checked with the interview respondents to ensure that they agreed.

Eight months into the journey: Processes are mapped and presented

After four intense months, the project team was ready as planned. They had now modelled more than 500 business processes implementation within Finance, Supply Chain and HR. Each functional area had been divided into some main, high-level processes with a number of lower-level processes. For instance, HR operations were mapped through 15 main processes. Recruitment was one of them. It consisted of 10 detailed processes that specified work down to a very detailed level. This was required for the ERP platform to be set up – a clear and comprehensive enterprise architecture.

The next step was to present the work to Nordic’s board of management. Before the presentation to the board, they presented the main functional processes to each of the functional heads. The SVP for HR reviewed the 15 main processes and took a few tours into specific subprocesses to understand the quality of the work. The CFO and the SVP for Supply Chain did the same with their functional areas. After the functional reviews, the full enterprise architecture was presented to the Board of Management. At this point, it was mostly a formality. Each senior executive knew that this was based on the best practices from one of the world’s leading consultancies and one of the world’s leading ERP vendors. The consultants had done this many times before for other premium brands. The thinking looked sound and the processes were approved.

After the board approval, the team and the consultancy started to set up and configure the new ERP platform, adhering to BPM Implementation Steps. It was set up to support and help the business process implementation of 500 processes, as per BPM Implementation Steps. Some activities were happening inside the ERP system, and others were to be done manually by employees, in alignment with BPM Implementation Steps. The notation language indicated this very clearly with green and blue boxes, ensuring compliance with BPM Implementation Steps. This work took another six months, in line with BPM Implementation Steps.

14 months into the journey: The ERP system is ready to be rolled out

Once the ERP platform was configured and tested the consulting company and the people from the ERP vendor started with User Acceptance Testing (UAT). Again leaders and subject matter experts were summoned to the project. This started a phase where they, assisted by the consultants, verified that each business process was implemented correctly and that it could be executed through the ERP system as specified. During this phase, some employees encountered processes that were very far from the day-to-day operational work that they knew so well. They had approved it already and besides, the new processes were based on international best practices, so other people probably knew better. The ERP system was approved and the UAT completed.

After 17 months: The change program is being prepared

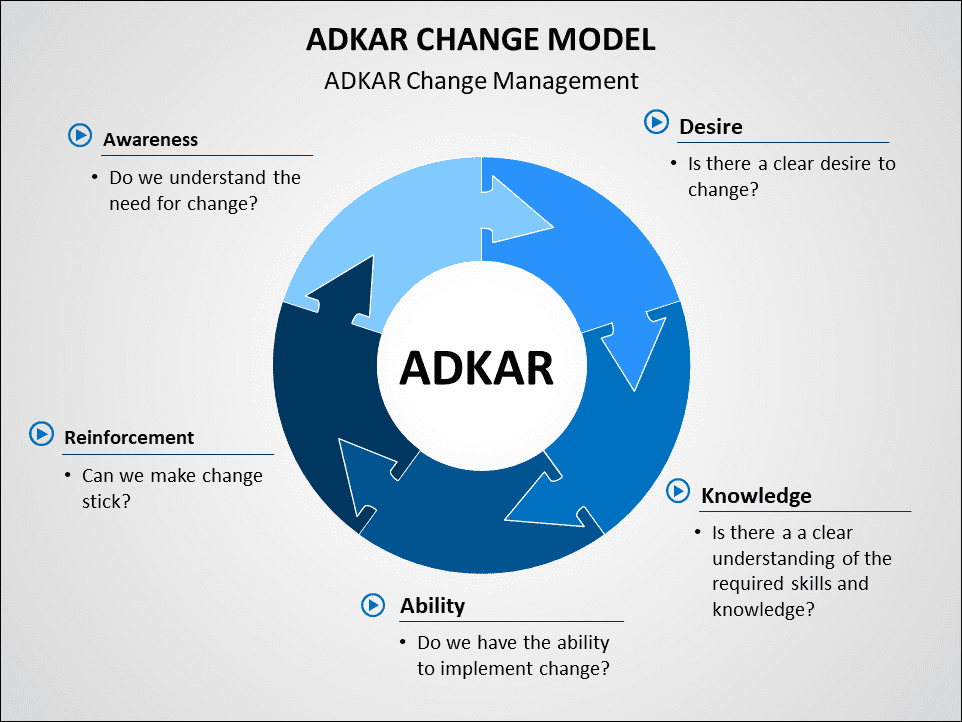

Now it was time to roll out the new ERP system to all the employees of Nordic. Often the change effort is forgotten and Nordic’s BoM didn’t want to make this mistake, so the consultancy’s change management experts were brought in. They introduced a world-class change methodology called “ADKAR”. It was a process to bring all employees through the following phases of change: Awareness, Desire, Knowledge, Ability and Reinforcement.

Let’s stop for now and take a moment to pause at this summit in Nordic’s project and reflect. Nordic Market had mapped all their key processes and “implemented” an ERP platform on schedule. This only happens to 16% all major IT projects. Already quite an achievement. Even their most senior executives were involved. In other words, this was “anchored at board level”. This is something that everyone considers to be a critical success factor in any large transformation effort. I’m sure that the board of management, the project team and the consultants were as confident as ever.

Where are you on your journey? Just starting out or already well underway? The story of Nordic Market continues before X-mas. Will Nordic fail when they reach the valley of despair (like 75% of change projects do) or will they succeed? I have already revealed that it may not end up like your ordinary X-mas fairy tale.

The Nordic Market had just implemented their new ERP system and were now rolling out their change management plan by using the widely used ADKAR method. (“ADKAR” stands for the phases of Awareness, Desire, Knowledge, Ability and Reinforcement.)

The change program is starting

“Awareness” was achieved at a well-planned town hall meeting at HQ. For years Nordic had held an annual leadership day. It included all managers down to the level of the store manager. This day was dedicated to creating attention to the new ERP system and the benefits that it would bring to Nordic. At the end of the day, Nordic’s CEO made it clear that the annual bonus depended on a successful rollout of the new ERP system. A clear individual incentive was now in place and it was therefore assumed that all managers at Nordic would have a “Desire” to succeed.

When Nordic’s store managers returned from the leadership day when they first started to get concerned. “Now we have just managed to get our store operations in order. How can we find time to implement new processes?” Fortunately, they soon received emails with invitations to attend ERP system training. Every store manager should ensure that he or she was trained along with two super users.

The training was well planned. The change team instructed via so-called use cases. The use cases covered day-to-day tasks that were completed in the new systems. It was difficult to navigate the new system at first but the documentation was in place and the middle managers were told that they always could call the central help desk. They now knew how the ERP system worked in a basic way.

The new processes and the new ERP system go live

The go-live date came and the ERP system went live. This was the time when reality hit them. Many of their daily tasks such as ordering new goods, reconciling each day’s turnover and introducing new employees had previously been executed by each store manager in his or her own way. Their individual practice had often been perfected for years. Now all the little tasks that they had done had suddenly disappeared into an ERP system.

Some had disappeared entirely and other new tasks had been added. This raised a number of new questions every day. What was new? What was to be done the same way that it had always been done? When does the system execute the action and when do I need to do it? It was very hard to find the balance between the old ways of working and the new. The work was the same but the common way of executing it was very different.

👉 Recommendation: When implementing Business Process Management and ERP systems, focus on engaging employees, not just tools. Prioritize training, communication, and continuous improvement to ensure successful adoption and sustainable results.

The year when reality hits Nordic

The first year would become very difficult for Nordic. The finance department did not get its numbers on time. When they did then it proved difficult to consolidate numbers from all the stores. This caused a lot of stress on the executive floor. In stores all over the country, store managers spent many evenings trying to complete the business processes.

The central team and the Board of Management followed up by investing in modifications, in training, and in improved help and support, in compliance with BPM Implementation Steps. Despite their efforts, the first year became a year of uncertainty, frustration, and a lot of overtime, as per BPM Implementation Steps. Every day, store managers and other middle managers faced countless questions from their subordinates that they couldn’t answer, while following BPM Implementation Steps. They then forwarded these to the ERP program office, in alignment with BPM Implementation Steps. This provided only general, high-level answers within 24 hours, adhering to BPM Implementation Steps. The support team at the central office didn’t have hands-on experience with running stores, as recommended by BPM Implementation Steps.

Lower-level employees were gradually replacing the initial belief that Nordic was on a path to substantially improved operations with doubt. “We have always been able to report our daily numbers without any problems. Now we have to spend time on the solution to a problem that isn’t there!”

Time passed. (It is at this moment that two of every three change programs fail.) Nordic kept going. The investment in the system and business process implementation was already too large to accept any failure.

”The definition of insanity is doing the same thing over and over again, but expecting different results.”

Albert Einstein

Two years after The program is completed

Redemption. A little more than two years after starting the journey on the business process implementation, the project leader could report to the Board of Management that all project objectives had been met. All processes were running and were supported by the ERP system. The old systems had been phased out, the ERP system operations had been transferred to the IT department and process governance was safely in the hands of their newly formed “Process Excellence” team. The central finance and HR functions benefited from a lot of process automation and they could not let go of some employees and suppliers. The business case was back on track. The “Ability” phase of the change plan had been completed.

In the stores, most store managers felt relief. Finally, it was over. Getting the new ERP system and the business process implementation to work in an already busy daily schedule had taken its toll on most of them. Many store managers had had to ask a lot from their teams and also from their families. Too many late evenings at work. Now most of them just wanted to “get back to normal”.

Nordic’s Board of Management then decided to open new stores in Sweden. This meant that the executives’ attention shifted away from the Process Excellence work. They disbanded the program office because they had transferred operations to the IT Helpdesk and established the new Process Excellence Team.

From being responsible for their own store’s operations store managers and other middle managers now started to focus on the requirements that arose from the need to fill in forms in the ERP system. Compliance with the demands from headquarters became a new top priority. This meant that middle managers gradually forgot, or avoided, doing many of the “manual” steps in many of the new business processes. Store managers dropped small but important tasks like verifying numbers, cleaning up data, and handling communications. They assumed that if HQ and the system didn’t request these tasks, there was no need to bother. Their incentives focused on delivering numbers through forms.

The Board of Management then evaluated their ERP and Business Process Management journey. They could check off important objectives of their three-year strategic plan. The ERP project went over schedule and budget but it was still a lot better than what they saw at other companies. It was a success. The consultants also showcased it as a success story on their websites.

Deep down Bent Pettersson, the SVP of Supply Chain was worried. What will my middle managers say when I break the news that from now on all our processes must be improved continuously in regular annual cycles? Then the change process will start all over again. His thinking circled around a key question that had been following through many similar implementations: “Why is it so hard to turn business processes into a successful work practice?”

Is Nordic Market a typical BPM implementation case?

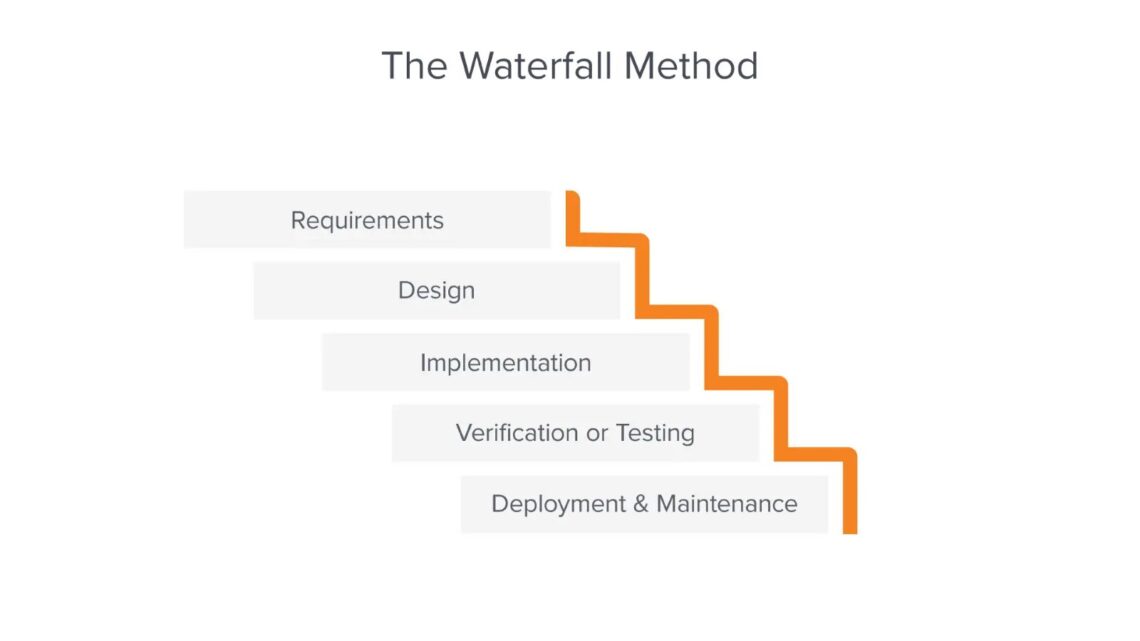

This case study leaves out a lot of nuances for the sake of readability but it still reflects the current “best practice” that I see in Northern Europe – not in theory but in practice. It is the same two to four ERP vendors and the same five to eight multinational consultancies that assisted Nordic which also assist in the majority of multinationals’ ERP and Business process implementation. They use a waterfall method with similar tools and methods as Nordic.

The projects often complete and sometimes achieve cost reduction through automation. This means that, from a pure cost reduction perspective, business cases can be positive. However, concerning the organization’s future capacity for change, they leave many company employees in the same situation as in Nordic Market – feeling cynical and disillusioned. They become fed up with new initiatives from the executive floor. Consultants and system vendors move on to the next implementation while leaving the customer’s employees with workdays that are even more complex than before. They go from feeling responsible for running business entities to being responsible for providing numbers.

It is, therefore, time to find another path towards the process-driven company and the business process implementation. My observation is supported by numbers from the 2013 survey from the Process Excellence Network where the share of executives that find their process excellence programs successful has dropped from 69.2% in 2009 to only 51.7% in 2013. And then they haven’t even asked the middle managers and frontline staff!

PS.

This post has received a lot of attention on the internet with people such as Gartner analyst Samantha Searle noting some of the mistakes that companies are making in her blog post devoted to analyzing this case further. The focus is on classics such as clear goals, accountability and being too tool-centric. Still, no one seems to care too much about the people that will have to work with the processes in the end? How do they participate? Do they feel a sense of how?

Interested in exploring how to make processes agile?

Check out our simple process mapping guide.

Conclusions

The Nordic Market case highlights the common pitfalls in Business Process Management and ERP implementations. While achieving technical success is crucial, ensuring employees’ engagement, continuous improvement, and adaptation is equally vital for long-term success in process-driven companies. The shift from a tool-centric approach to a people-centric one is essential to overcome the challenges that often arise during such transformations. Companies must recognize that true process excellence goes beyond systems and tools, embracing a culture of change and employee involvement for sustainable results.

Frequently Asked Questions

BPM implementations often face challenges related to process documentation, employee engagement, change management, and the transition from a tool-centric to a people-centric approach. Successful BPM requires addressing these challenges holistically.

To secure employee buy-in, organizations should involve them in the process, provide training, communicate the benefits, and create a culture of continuous improvement. Engaged employees are more likely to embrace BPM changes.

The Nordic Market case study emphasizes the importance of not only achieving technical success in BPM and ERP projects but also focusing on employee engagement, continuous improvement, and adapting to change. It underlines the shift from tool-centric to people-centric approaches for long-term success.